Chip manufacturing giant, GlobalFoundaries, has struck up a unique arrangement with an ambitious quantum startup to share knowledge that could help turn standard photonics processing technology into a qubit factory. This process and materials understanding could fuel a new wave of photonics innovations for broader manufacturing.

There are several reasons why the commercial quantum computers of today are not ready for primetime.

From a lack of robust error correction across a large enough qubit count to solve meaningful problems to the touchstone matter of doing both at reasonable cost, the limited quantum hardware market is stalled. This is not to say there is a lack of immense progress but with each quantum systems maker rolling their own qubits, casing, and software stack, the efforts are investment-limited.

Put another way, what if quantum computing devices could be reliably produced with standard (albeit tuned) semiconductor manufacturing processes? There are novel materials science and other technical challenges, but if quantum hardware makers could work with the fabs, how much faster might we get to mainstream quantum computing, especially with the vendor ecosystem focused on building tooling for users instead of handling A-Z manufacturing of their own devices and systems?

The impact could be enormous, not just for the quantum computing ecosystem but for the expansion of silicon photonics in current networking and datacenter realms, Anthony Yu, VP of Photonics at GlobalFoundries (GF) tells The Next Platform. But this will take the physics and materials understanding from public/private partnerships that openly explore manufacturing capabilities inside GF and how those map to building fault-tolerant, large-scale quantum machines—the kind big enough to actually address meaningful real-world problems.

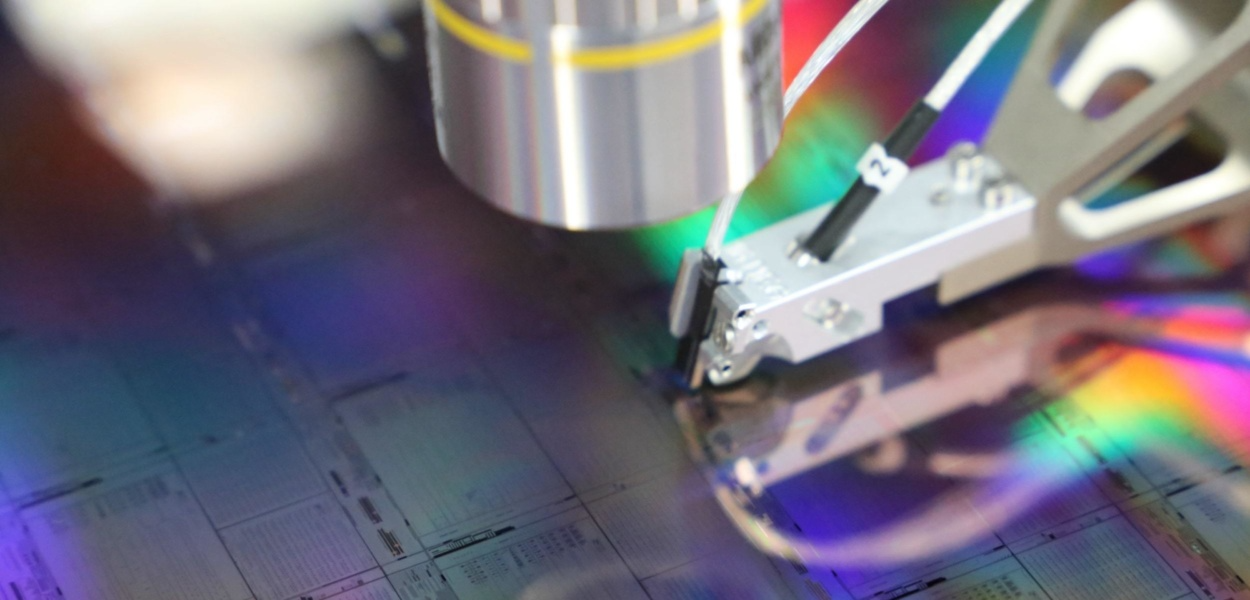

Yu and his team have been working with quantum computing startup, PsiQuantum, to work toward building a million-qubit quantum system based on existing manufacturing processes.

“We were unique in saying from the beginning building this kind of quantum system would need error correction and at least a million qubits to do anything useful,” Pete Shadbolt, co-founder of PsiQuantum tells us.

“The only reason we could afford to shoot straight for that goal is via silicon photonics and the semiconductor industry. Our idea was if we could figure out a way to make use of the trillion dollars and 50 years of work that’s gone into that industry. We knew it wouldn’t be possible to do much with small qubit-count machines but now we’re in the production line at GF.”

Yu admits this kind of knowledge-sharing partnership is “unusual” for GF but necessary if the chip manufacturer wants to be far ahead of the curve for both the important networking and compute functions of silicon photonics and its potential role in building large-scale quantum computers.

“No other foundry is doing what we’re doing, from using 300mm VLSI manufacturing to this work,” Yu explains. “PsiQuantum put engineers into GF to develop features on top of our manufacturing environment. We’re using that already to build chips for phones and computers and now with new materials being introduced we can support a one million-plus qubit quantum computer that can operate at low temperatures and use advanced materials for optical switching. This is a synergistic relationship because the materials let me move R&D forward in photonics within our disciplined manufacturing approach and yes, it’s atyptical, but this is what we both need.”

“My opinion is that we’re in a different era and dimension of computing. The types of problems we have demand the benefits of quantum and superposition and entanglement. From an industry standpoint, rather than signaling we’re going to be tackling computing problems through the pursuit of pure Moore’s Law optical lithography down to 7nm and 5nm, we’re looking at attacking the problem with photons and unique materials, which will allow computational platforms like quantum to take on problems that would otherwise take years,” GF’s Yu says.

“Hopefully, we’re signaling that we’re forward-thinking by putting forward manufacturing technology that moves beyond electrons. Although CMOS will continue to be our bread and butter, we are looking at new materials and light-based qubits to solve the problems of the twenty-first century,” he adds.

It is not clear from the conversation just how much investment this venture into the qubit production world has required. “We’re building chips for PsiQuantum in our of our two New York fabs, the one in Malta, NY is a $15 billion fab with capacity to produce 500,000 wafers per year. All photonics work is centered in the U.S. and R&D in photonics is significant at GF,” Yu explains. “Capital for 300mm tools is significant, new materials as well. We’re expanding our public/private partnerships because we know quantum is important to the U.S. and the semiconductor industry is as well.”

It is a smart way for GF to leverage all of its existing assets in silicon photonics, which go back over a decade. When GF acquired IBM Microelectronics and its two fabs and 6,000 employees (Yu included), it also captured twelve years of IBM Research work on photonics manufacturing and materials. Yu spun up the photonics business unit inside of GF and has watched it grow rapidly. “We’ve been concentrating our foundry offering for datacenter and interconnects, for the big demands from cars, and streaming with high bandwidth and low loss and power.” But the prospect of quantum became clear when PsiQuantum approached Yu and team with an idea that could benefit both companies.

“Quantum computing has a reputation for being the stuff of science fiction with exotic materials, fabrication, and operating environments,” Shadbolt says. “The work we’re announcing now is bringing to scale, making it reliable and manufacturable. To do that, we put tools into the production line at GF and have been through a large number of silicon wafers to take that from a prototype device to something we can now build integrated with the rest of the silicon photonics stack. In the end, we have high performance devices that all work because of the extremely good process control and production at GF.”

“In the past year, we have experienced a decade of technological change. Now, due to the digital transformation and the explosion of data we are faced with problems that require quantum computing to further accelerate the Renaissance of Compute,” said Amir Faintuch, senior vice president and general manager of Compute and Wired Infrastructure at GF. “PsiQuantum and GF’s partnership is a powerful combination of PsiQuantum’s photonic quantum computing expertise and GF’s silicon photonics manufacturing capability that will transform industries and technology applications across climate, energy, healthcare, materials science, and government.”

Be the first to comment